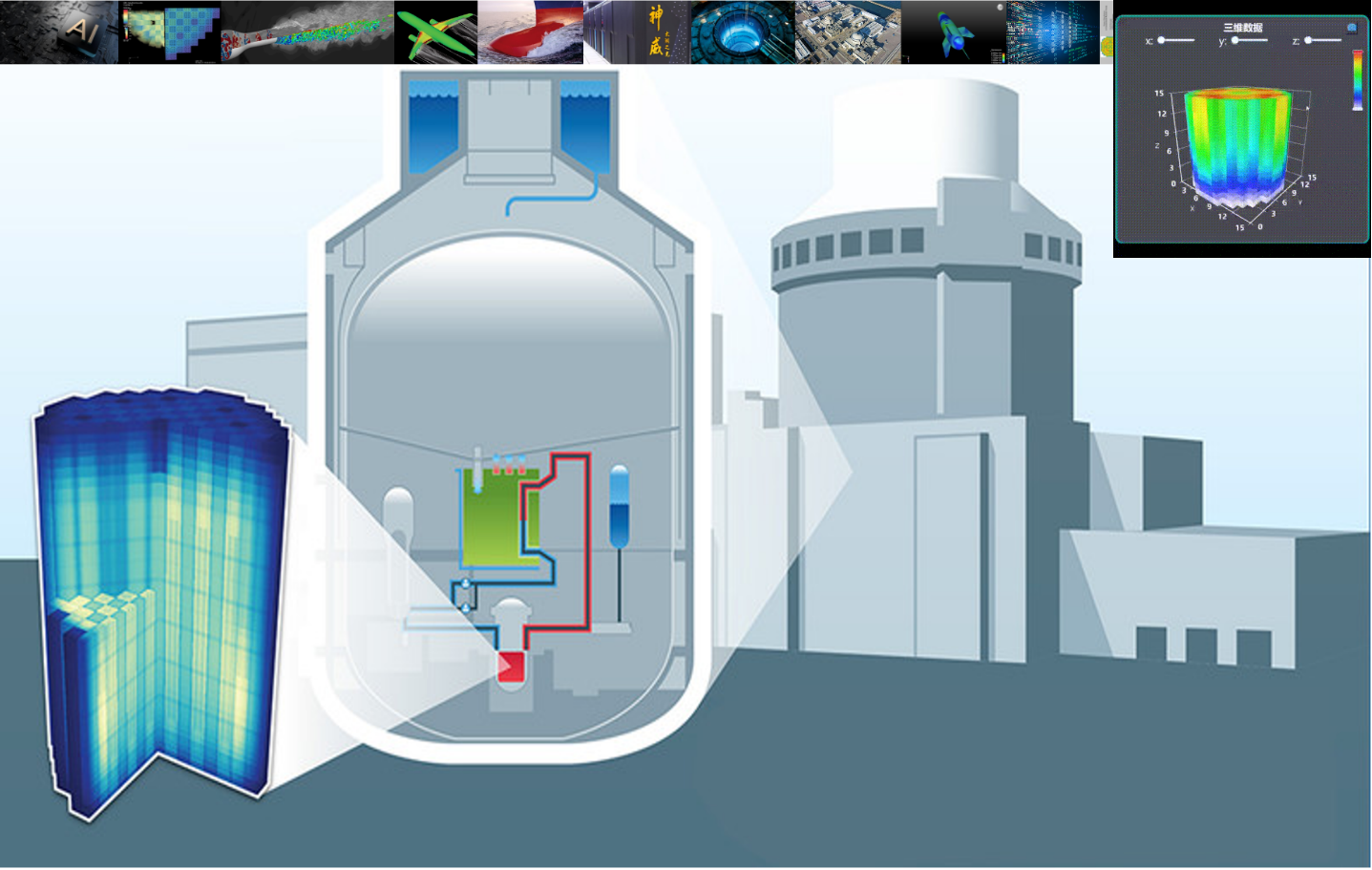

Intelligent robots are core equipment in modern intelligent manufacturing, representing the in-depth integration and innovative convergence of disciplines such as mechanical engineering, artificial intelligence, sensing, and control technology. Perception-interaction, autonomous decision-making, and precise execution technologies are the core pillars of intelligent robots, providing intelligent solutions and strategic technical support for fields such as industrial production, civil services, and special operations.

This Research Platform for Intelligent Robot Technology and Applications is positioned to "lead with basic research and drive innovation through interdisciplinary integration." It closely aligns with the national strategy for intelligent manufacturing development and the demand for equipment autonomy, focusing on high-level frontier research in intelligent robot system modeling, planning and control methods, and new scene-adaptation technologies. Its scope includes human-robot collaborative interaction, autonomous navigation and operation of mobile manipulators, and optimization of robot dynamic behaviors.

Relevant research results have been applied in scenarios such as flexible production lines for industrial robots and multi-robot operation systems. The research platform will continue to provide key technical support and application solutions for intelligent robots.

Partner Institutions:

State Key Laboratory of Mechanical System and Vibration; Yuanzhi Robot Research Institute

Platform Principal:

XIONG Zhenhua, Tenured Professor, mexiong@sjtu.edu.cn